Press

Read our press releases, you can find more press material and older press releases on our Cision page.

Read our press releases, you can find more press material and older press releases on our Cision page.

NIMO in Hova has carried out a thorough development of the painting. Thanks to the measures implemented, it has gone from 2 shifts to only day shifts, while the number of painted items has increased. In addition, energy consumption has been cut in half. The recipe for success is the optimisation of the hanging technology, increased conveyor speed and new procedures for preparing materials. "It is also thanks to the great commitment and expertise of our employees that we have now achieved these amazing results," says Mikael Fröjdendahl, production manager for sheet metal and painting at Nimo.

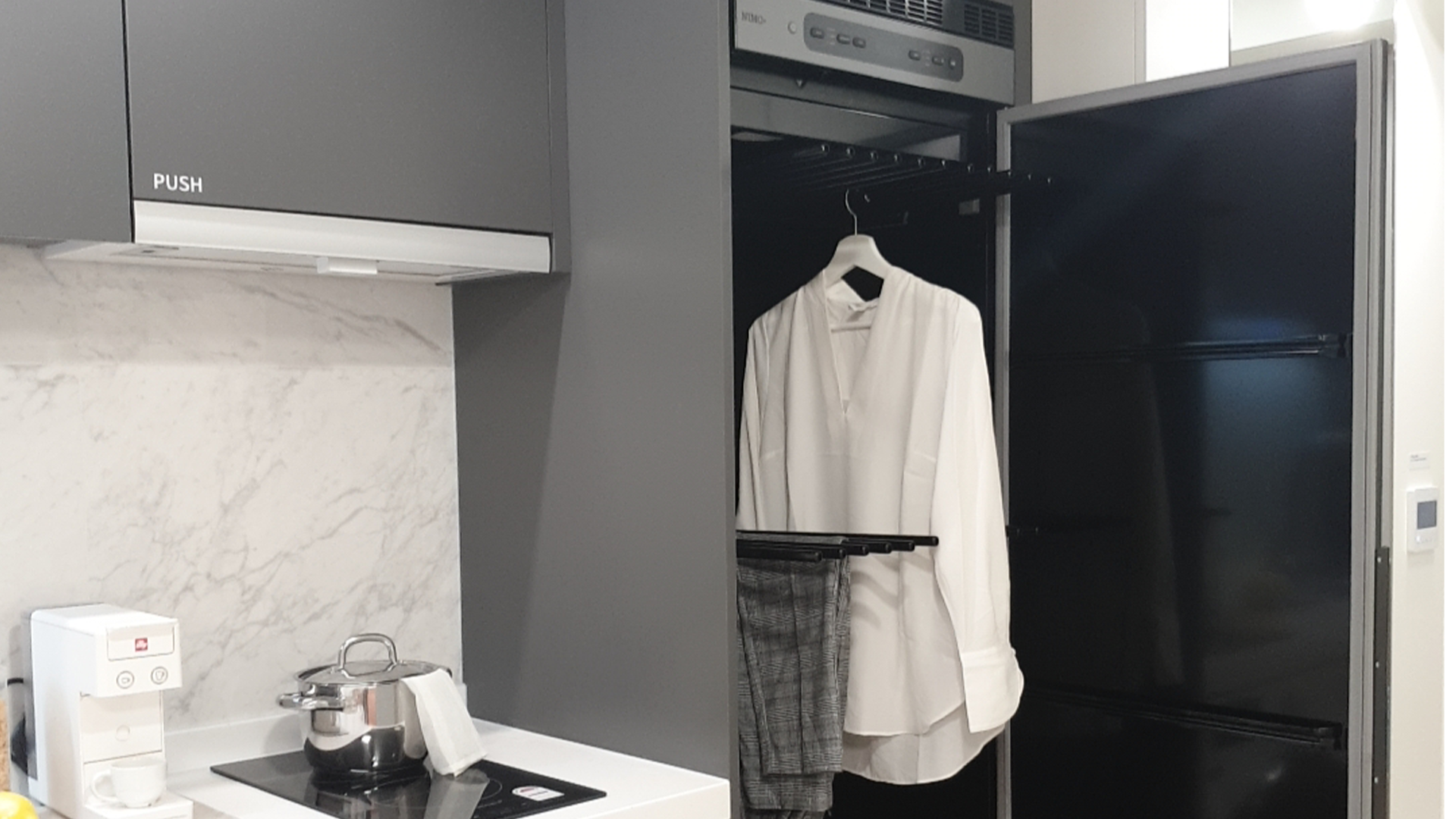

NIMO has supplied tens of thousands of drying cabinets to the South Korean market since 2002 and has now received a new order of over 200 Sensor Dryer 1900 F drying cabinets from local retailer Sam Deug Trading Co. The order comes from one of many ongoing residential projects in which Nimo is involved. "Thanks to Nimo's good reputation, high quality, good functionality and energy-efficient drying cabinets, our retailer has once again won a major tender. We are also very well positioned for upcoming tenders, says Rickard Hallberg, International Key Account Manager at Nimo.

Sweden's leading drying cabinet manufacturer NIMO is investing in a new brand platform and graphic profile, while launching a new website to support the continued digitalisation of customer dialogue. “Our sights are set on international growth, and we need to communicate what we believe in and be more digitally accessible to our customers. The drying cabinet itself is the result of a sustainable way of thinking about textile care, and with the new brand platform we’re making the Nordic heritage clearer,” says Karin Kruse, CEO of NIMO.

Sweden's leading drying cabinet manufacturer NIMO in Hova had a very strong year in 2021, increasing its turnover by 15 percent despite the pandemic and supply chain problems. The company is now investing in a new IT environment further to digitise the business, is investing in new product launches in 2022 and will soon introduce an updated brand platform.“The aim is to work more efficiently and sustainably and to be able to meet growing demand in the Swedish and international markets. Investing in a new IT environment, brand platform, graphic profile and website are essential elements for successful growth with both sustainability and profitability in focus,” says Karin Kruse, CEO of NIMO.

The classic drying cabinet now adds a feature that could benefit preschools and other businesses. According to a study conducted by RISE, on behalf of NIMO, it was established that with proper handling, both the common norovirus (winter vomiting disease) and Sars-CoV-2 (Corona) are inactivated by the heat in NIMO’s Easy Dryer 1900 drying cabinet. “We’ve always known that high temperatures are necessary for re-impregnating different materials and that heat can also remove a degree of dirt from clothes. The drying cabinet wasn’t intended to remove viruses, but it’s a great added value,” says NIMO’s CEO Karin Kruse.

Nimo invests millions in production. During the autumn, the company has installed a specially ordered laser cutting machine, a handling machine and brand new software, which means increased efficiency while the factory has been able to lay the technical foundations for the future.